In the diverse world of polymers, Polyvinyl Chloride (PVC) stands out as one of the most versatile and widely used materials. From the waterproof “WPC/PVC” boards used in modern Indian kitchens to the durable chemical tanks in industrial plants, PVC is everywhere.

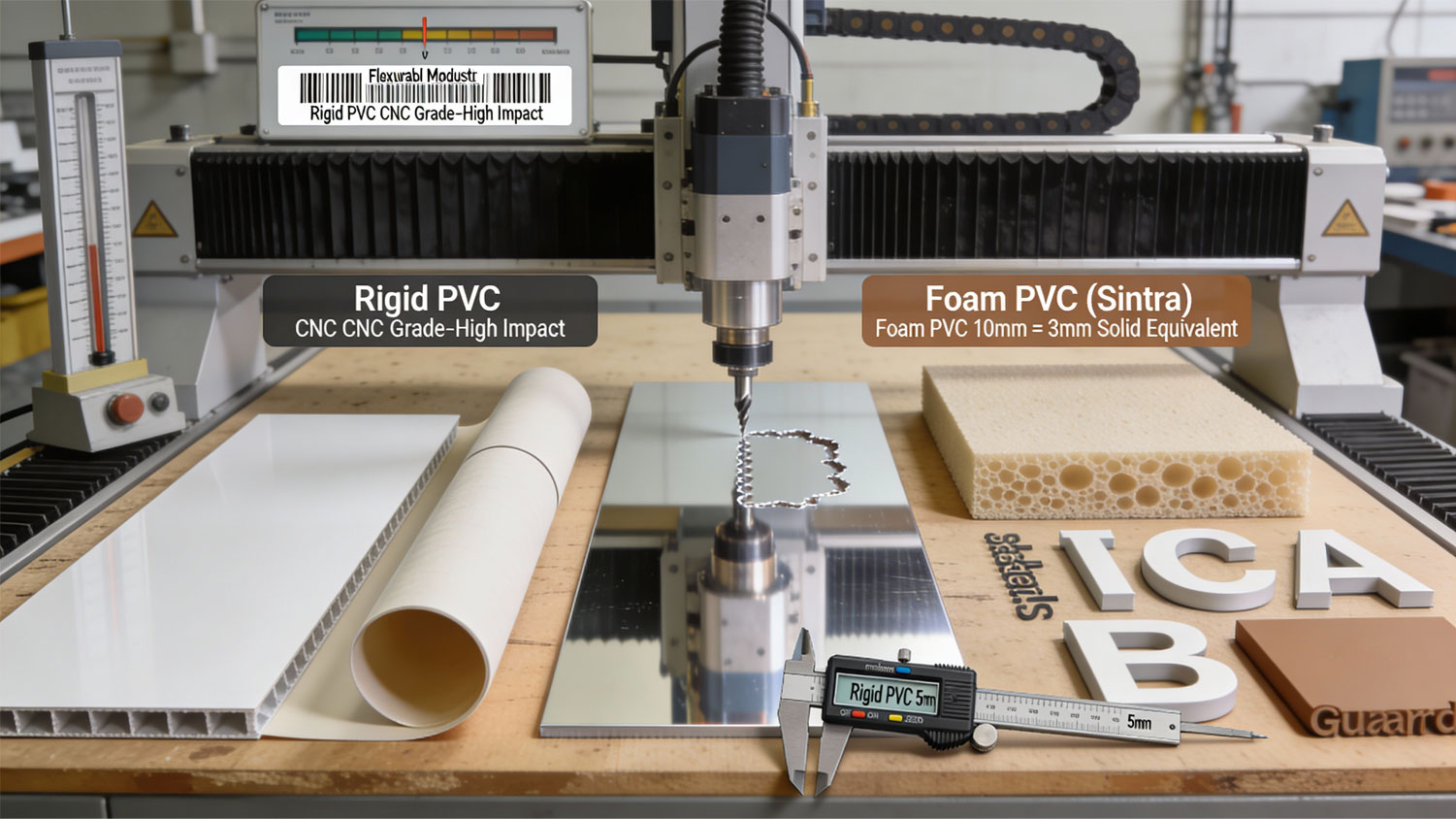

For a CNC workshop, PVC is a “friendly” material. It cuts smoothly, doesn’t splinter like wood, and doesn’t crack as easily as acrylic. However, to truly excel in PVC routing, you must understand the nuances of the material grades. At Kataria Tech Zone, we build machines that handle everything from feather-light foam to rock-solid industrial PVC.

1. The PVC Spectrum: Rigid vs. Flexible

When we talk about CNC routing, we are almost exclusively dealing with Rigid PVC (uPVC). Flexible PVC (the kind used in hoses or cable insulation) is rarely routed because its “rubbery” nature causes it to wrap around the bit rather than being cut.

Rigid PVC (uPVC)

- CNC Compatibility: Excellent. It produces clean, continuous chips and holds a sharp edge.

- Key Properties: High impact resistance, chemical resistance, and excellent fire-retardant properties (Self-extinguishing).

- Common Uses: Electrical trunking, window profiles, and chemical valves.

2. Foam PVC vs. Solid PVC: Which One Should You Route?

This is the most common question we receive at Kataria Tech Zone. The choice depends entirely on your end application—Weight vs. Strength.

A. Foam PVC (Expanded PVC / Sunboard / Forex)

Foam PVC is created by “expanding” the material to create a honeycombed internal structure. It is much lighter and more economical than solid sheets.

- The Routing Experience: It cuts like butter. You can use very high feed rates (6–10 meters per minute) on a Kataria CNC.

- Edge Quality: The edges are slightly porous. If you are painting the edge, it will require a sealer.

- Best For: POP (Point of Purchase) displays, exhibition stands, signage, and lightweight ceiling panels.

B. Solid PVC Sheets

Solid PVC is dense, heavy, and incredibly tough.

- The Routing Experience: It requires more “muscle.” You need a high-torque spindle (at least 3kW to 5.5kW) and slower feed rates to prevent the tool from overheating.

- Edge Quality: Perfectly smooth and non-porous. It can be polished to a high sheen.

- Best For: Chemical tanks, laboratory equipment, heavy-duty industrial templates, and outdoor furniture.

3. Why PVC is the “Perfect” Material for CNC Beginners

If you are new to the CNC world, PVC is the best material to start with for several reasons:

- Low Tool Wear: PVC is non-abrasive. Your carbide bits will last significantly longer cutting PVC than they will cutting MDF or Plywood.

- No Grain Direction: Unlike wood, you don’t have to worry about “tear-out.” You can route in any direction with the same result.

- Chip Evacuation: PVC chips are relatively heavy and don’t float in the air as much as MDF dust, making your workshop cleaner.

4. Technical Mastering: Bits, Speeds, and Feeds

Even though PVC is easy to cut, doing it perfectly requires the right setup on your Kataria Tech Zone machine.

Tooling Choice

- Up-cut Single Flute: The best choice for PVC. It pulls the heat and the chip up and out of the cut.

- Down-cut Bits: Use these only when cutting very thin Foam PVC (3mm or less) to prevent the sheet from lifting off the vacuum bed.

The “Melt” Factor

PVC has a relatively low melting point. If your bit stays in one spot too long, the plastic will liquefy and “weld” itself to the tool.

- Kataria Tip: Increase your Feed Rate. If you see “hair” or “strings” instead of “chips,” your machine is moving too slowly. A Kataria CNC with Servo Motors is ideal here because it can maintain high speeds without losing steps.

5. Applications: Transforming PVC with Kataria CNCs

With the right machine, you can dominate these Indian market segments:

I. Modular Kitchens (PVC Boards)

Termite-proof and waterproof kitchens are the current trend in India. Using a CNC to cut PVC/WPC boards for cabinets ensures 100% accuracy in hinge holes and drawer slides.

II. Jali Work and Partitions

Foam PVC is the most popular material for decorative Jali work. A Kataria CNC can cut a complex 8×4 ft Jali in under 30 minutes.

III. Industrial Gaskets and Washers

Solid PVC is routed into custom shapes for the plumbing and chemical industries, replacing expensive injection molding for small-batch runs.

6. Why Kataria Tech Zone is the Leader in PVC Routing Solutions

Our machines are built to handle the specific demands of PVC fabrication:

- High-Speed Spindles: Our air-cooled or water-cooled spindles provide the RPM needed to keep the cut “cool.”

- Z-Axis Precision: Vital for “half-cuts” or “V-grooving” in PVC boards for folding.

- Strong Vacuum Tables: PVC sheets, especially thinner foam grades, tend to bow. Our vacuum tables ensure the sheet is perfectly flat for consistent depth.

Conclusion

Whether you are working with the lightweight flexibility of Foam PVC or the industrial grit of Solid Rigid Sheets, PVC offers a world of profitability. Its ease of use, combined with the precision of a Kataria Tech Zone CNC Router, allows you to create products that are waterproof, durable, and visually stunning.