In the world of plastic fabrication, acrylic is often called the “King of Plastics.” Whether you are manufacturing glowing LED signage, high-end furniture, or medical-grade components, acrylic offers a clarity and versatility that few other materials can match.

However, for a CNC workshop, acrylic can be a “dream” or a “nightmare” depending on your technical knowledge. At Kataria Tech Zone, we believe that the difference between a jagged, melted edge and a crystal-clear finish lies in the synergy between the material and the machine.

In this guide, we dive deep into why acrylic is the ultimate material for CNC routing and how to master it using Kataria Tech Zone’s high-precision equipment.

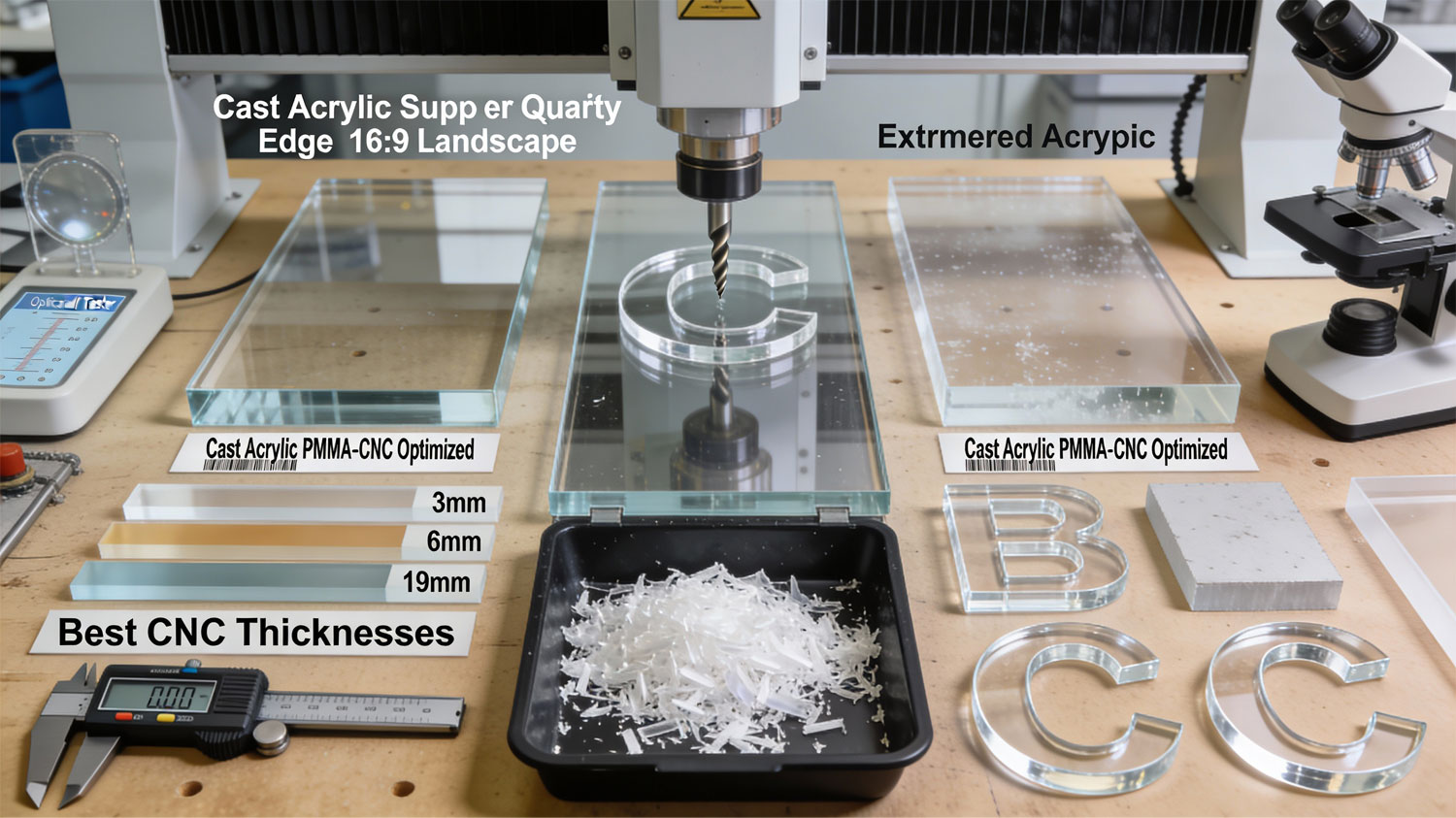

1. The Chemistry of Success: Cast vs. Extruded Acrylic

Not all acrylic sheets are created equal. In the Indian market, you will primarily encounter two types: Cast and Extruded. Choosing the wrong one for your CNC project can lead to wasted material and broken bits.

Cast Acrylic (The Premium Choice)

Cast acrylic is made by pouring liquid ingredients into molds.

- Why it’s great for CNC: It has a higher molecular weight, meaning it doesn’t melt easily. When the CNC bit hits the material, it produces clean “chips” rather than sticky “goo.”

- Best For: Engraving (it turns a beautiful frosty white), 3D carving, and high-end signage.

- The Downside: It is slightly more expensive and has a variable thickness (a 5mm sheet might be 4.8mm or 5.2mm in different spots).

Extruded Acrylic (The Economical Choice)

Extruded acrylic is pushed through a machine in a continuous process.

- Why it’s tricky for CNC: It has a lower melting point. If your CNC spindle speed is too high or your feed rate is too slow, the acrylic will weld itself back together behind the bit or clog the flute.

- Best For: Simple cut-outs, bulk manufacturing, and projects where cost is the primary concern.

- The Downside: It does not engrave cleanly (it tends to smear) and is more prone to cracking under stress.

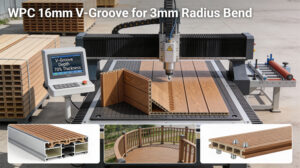

2. Thickness Guide: Matching Material to Application

Choosing the right thickness is essential for structural integrity and aesthetic appeal. Here is a quick reference guide for common CNC applications:

| Thickness | Common Applications | CNC Tip |

| 2mm – 3mm | Photo frames, light box faces, small stencils. | Requires a high-vacuum bed to prevent the sheet from “lifting” during the cut. |

| 5mm – 8mm | Standard 3D letters, decorative partitions, trophies. | The “Sweet Spot.” Easy to cut in a single pass on a Kataria CNC. |

| 10mm – 15mm | Heavy-duty signage, furniture legs, retail displays. | Requires multi-pass cutting to maintain vertical edge accuracy. |

| 20mm – 50mm | Architectural features, thick “ice-block” trophies. | Requires specialized long-reach bits and mist cooling systems. |

3. Achieving the “Crystal” Edge: Factors Influencing Quality

The hallmark of a high-quality CNC job is the edge finish. You want a “flame-polished” look straight off the machine. Here is how to achieve it:

The Spindle & Feed Synergy

Acrylic is sensitive to heat. To prevent melting, you must follow the rule: Large Chips = Less Heat.

- Spindle Speed: On a Kataria Tech Zone CNC, we recommend 16,000 to 18,000 RPM.

- Feed Rate: Keep the machine moving fast (approx. 3-5 meters per minute) so the bit spends less time rubbing and more time cutting.

Tooling (Bits)

Never use wood bits for acrylic. Use Single Flute “O” Flute Up-cut bits. The single flute provides a massive “valley” for the hot plastic chip to escape, preventing it from sticking to the tool.

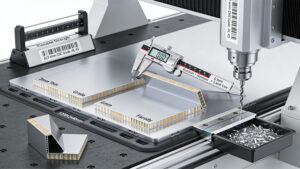

Rigidity of the Machine

Vibration is the enemy of edge quality. If the machine shakes, you will see “chatter marks” on the acrylic edge. This is why Kataria Tech Zone builds machines with heavy-duty steel frames and precision-ground linear rails. Our machines provide the stability needed for a glass-like finish.

4. Why Kataria Tech Zone CNCs are Built for Acrylic

Acrylic fabrication requires a level of finesse that standard “woodworking” CNCs often lack. Our machines are engineered with specific features for plastic fabricators:

- High-Frequency Spindles: Our spindles maintain constant torque at lower RPMs, preventing the “stalling” that causes melting.

- Mist Cooling Systems (Optional): For thick acrylic (10mm+), we offer mist spray attachments that lubricate the bit and cool the material instantly.

- Advanced Vacuum Manifolds: Acrylic sheets are often warped. Our high-pressure vacuum beds flatten the sheet completely, ensuring your engraving depth is consistent across the entire 8×4 ft surface.

- Servo Precision: Our servo-driven motors ensure that circles are perfectly round and corners are sharp, which is critical for letters that must fit into “push-through” signage.

5. Pricing and Profitability in the Indian Market

Acrylic is a high-value material. In India, a 3mm Cast Acrylic sheet costs roughly ₹2,800 – ₹3,500.

- The Value Add: A raw sheet of acrylic transformed into 3D LED letters can sell for 3x to 5x its material cost.

- The Risk: A single manual mistake or a “melted” cut on a manual router can ruin a ₹3,000 sheet instantly.

Investing in a Kataria Tech Zone CNC reduces your “rejection rate” to nearly 0%, ensuring that your profit stays in your pocket, not in the scrap bin.

6. Maintenance for Acrylic Success

To keep your acrylic cuts perfect, follow these three tips:

- Clean the Vacuum Filters: Acrylic chips are static and “jumpy.” They can clog your vacuum system quickly.

- Collet Care: Even a tiny bit of dust in the collet can cause “runout” (wobble), which ruins the edge finish. Clean your collets daily.

- Bit Sharpening: Acrylic is abrasive. Once a bit starts “screaming” or producing “hair” instead of chips, it’s time to replace it.

Conclusion

Acrylic is the bridge between functionality and beauty. When you master the art of routing it, you open doors to luxury markets that traditional woodworkers cannot reach. By combining the right material (Cast Acrylic), the right tooling (O-flute bits), and a Kataria Tech Zone CNC, your workshop becomes a powerhouse of precision.