Panel saws incorporate several advanced features that directly boost both cutting speed and accuracy:

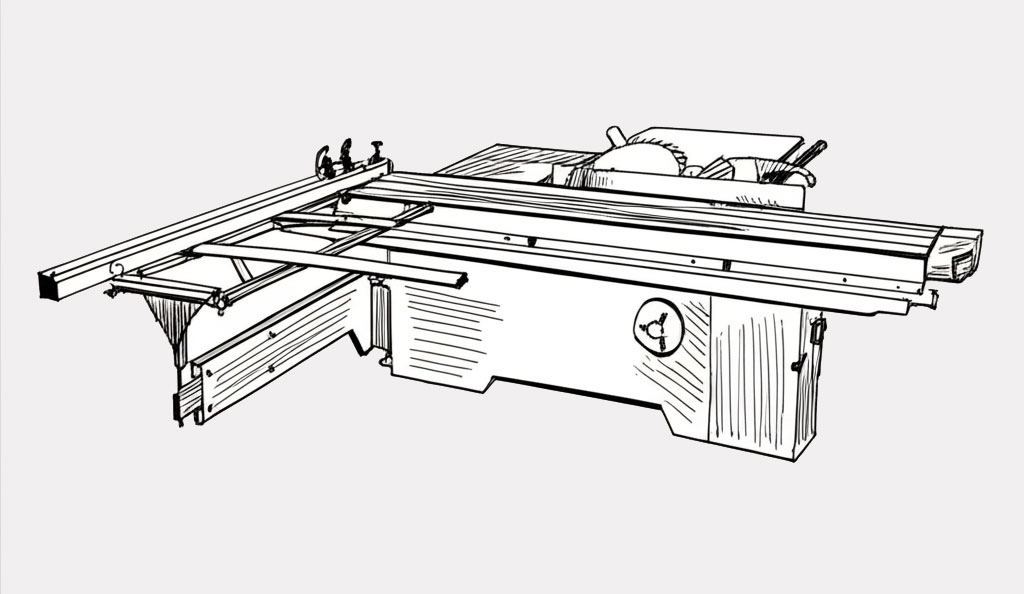

- Sliding Table or Carriage: Allows the workpiece to glide smoothly and securely through the blade, ensuring perfectly straight and repeatable cuts with minimal effort.

- Precision Rail and Guide Systems: High-precision linear rails or hardened guide bars keep the saw’s motion accurate and vibration-free, which is critical for consistent, square cuts, especially on large sheets.

- Powerful Motors: High-power main saw motors, sometimes assisted by servo motors, provide the torque and blade speed needed to cut quickly and cleanly through tough and thick panel materials.

- Scoring Blade Unit: An auxiliary blade that scores the surface of laminated or veneered panels just before the main blade passes through, preventing chipping and ensuring a perfectly clean, “ready-to-finish” edge.

- Pneumatic or Mechanical Clamping: Securely holds the material during cutting, preventing slippage and enabling both speed and precision throughout the process—especially valuable for stacked panels or automated operations.

- Digital Controls, Readouts, and CNC Integration: Modern panel saws offer digital measurement displays, the ability to program precise cut dimensions, and (for CNC models) store cut lists and optimize cutting patterns, all of which dramatically reduce setup time and operator error.

- Material Support Rollers and Tables: These features enable rapid panel positioning and feeding, reducing manual handling time and minimizing the risk of inaccuracies due to panel sag or movement.

- Quality Saw Blades: Carbide-tipped or specialty blades are designed for particular materials and cutting styles, ensuring faster cuts with less resistance and maintaining edge quality over many cycles.

- Safety and Dust Collection: Efficient dust extraction keeps the cut line clear for better visibility and accuracy, while advanced safety mechanisms allow higher working speeds with less risk.

In summary, panel saws achieve their superior speed and accuracy through a combination of mechanical stability, powerful motors, precision guides, specialized cutting and clamping systems, and advanced digital or CNC controls, all working together to optimize the cutting process.