Walk through any modern city in India—from the corporate hubs of Gurugram to the retail streets of Mumbai—and you will see the dominance of Aluminum Composite Panels (ACP). It is the skin of modern architecture. But for a fabricator, the beauty of ACP isn’t just in its finish; it’s in how effortlessly it can be shaped, folded, and cut using CNC technology.

At Kataria Tech Zone, we have engineered our CNC routers to handle the unique “sandwich” construction of ACP, ensuring that every groove is perfect for folding and every cut is burr-free. In this guide, we explore why ACP and CNC routers are a match made in heaven.

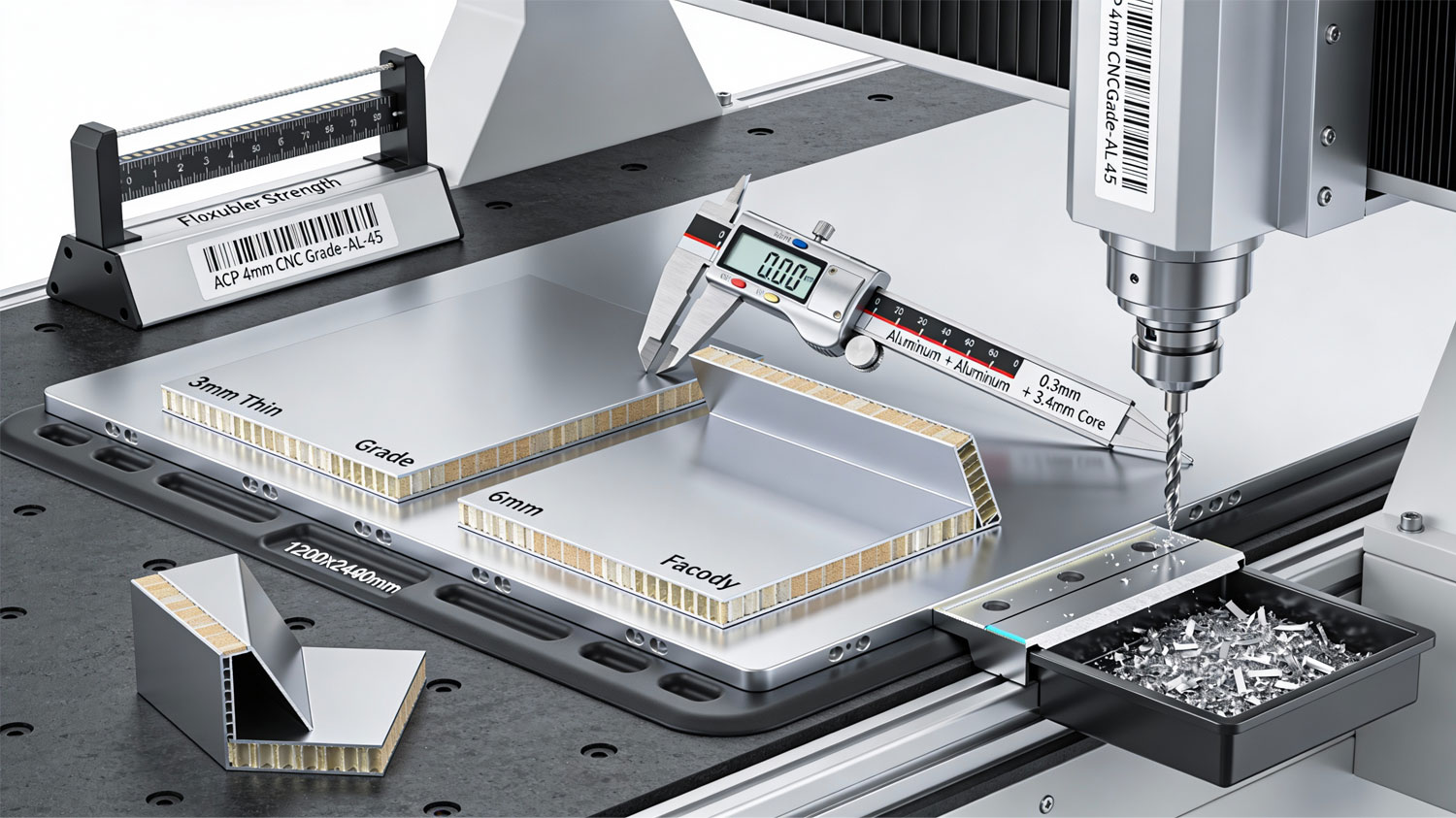

1. The Anatomy of ACP: A “Sandwich” Engineered for CNC

To understand why ACP is ideal for CNC routing, you first have to look at its layers. ACP consists of two thin sheets of coil-coated aluminum bonded to a non-aluminum core (typically Polyethylene or a Fire-Retardant mineral core).

The Material Synergy:

- The Aluminum Skin: Provides the rigidity and metallic finish. Aluminum is a “soft” metal, making it easy for CNC carbide bits to slice through without excessive heat buildup.

- The Core: The PE (Polyethylene) core acts as a dampener. Unlike solid aluminum, which can vibrate or “ring” during a cut, the composite core absorbs vibration, leading to a much smoother edge.

2. Key Material Properties for CNC Success

Why is ACP preferred over solid metal or wood for modern facades? The secret lies in its physical properties that align perfectly with CNC capabilities.

A. “V-Grooving” for Precision Folding

The most significant advantage of ACP is the ability to create “trays” or boxes through V-grooving. A CNC router can cut through the top aluminum layer and most of the core, leaving only the bottom aluminum skin intact. This allows the panel to be folded by hand into a perfectly sharp 90-degree angle.

- Kataria Tip: Our CNCs use specialized 90° or 135° V-bits to ensure the folding line is consistent across a 10-foot panel.

B. Lightweight yet Rigid

ACP is roughly 60% lighter than solid aluminum of the same rigidity. This makes it easier to handle on a CNC vacuum bed and reduces the wear and tear on the machine’s motors.

C. Thermal Stability

Unlike some plastics that expand and contract significantly with heat, ACP remains relatively stable. This ensures that a 2400mm panel cut in the morning will be the same size as one cut in the afternoon heat.

3. Thickness Standards and Panel Sizes in India

Understanding the standard dimensions available in the Indian market is crucial for optimizing your CNC “nesting” (arranging parts to minimize waste).

Common ACP Thickness Standards:

| Thickness | Usage Category | CNC Requirement |

| 3mm | Interior partitions, signage, kiosks. | Standard 3.175mm (1/8″) or 4mm bits. |

| 4mm | The “Industry Standard” for building facades (Exterior). | Requires high-torque spindles for long-duration cutting. |

| 6mm | Heavy-duty industrial applications, specialized cladding. | Requires multi-pass cutting to ensure edge quality. |

Standard Panel Sizes:

- 1220mm x 2440mm (4ft x 8ft): The global standard.

- 1220mm x 3050mm (4ft x 10ft): Very common in Indian architecture for floor-to-ceiling panels.

- 1220mm x 3660mm (4ft x 12ft): Used for large-scale warehouse cladding.

Why Kataria Tech Zone? Our CNC machines are built with oversized beds (e.g., 1300mm x 3100mm) specifically to accommodate these Indian standard sheets with room to spare for clamping.

4. Achieving Technical Perfection: The “Kataria” Way

Routing ACP is a balance of Spindle Speed (RPM) and Feed Rate. If you go too slow, the PE core will melt and stick to your bit. If you go too fast, you will “chatter” and leave a rough aluminum edge.

The Kataria Tech Zone Setup for ACP:

- Single-Flute Upcut Bits: We recommend polished carbide bits. The single flute allows the “spiral” to pull the hot aluminum chips up and out of the groove instantly.

- Vacuum Hold-Down: ACP sheets are thin and can “flutter.” Our high-pressure vacuum beds ensure the sheet is sucked flat, preventing the bit from vibrating or breaking.

- Mist Lubrication: While not always mandatory for 3mm, using a mist of oil/air lubricant on 4mm exterior-grade ACP extends your tool life by 300% and gives a mirror-finish edge.

5. Applications: What Can You Build?

With a Kataria Tech Zone CNC, your ACP capabilities go far beyond simple rectangles:

- CNC Perforated Facades: Create intricate “Jali” patterns in aluminum for modern building skins.

- 3D Signage: Cut and fold 3D letters for weatherproof outdoor branding.

- Modular Kitchens: Using ACP for interior cabinetry in high-moisture areas.

- Bus Body Building: Precision-cut panels for the automotive and transport industry.

6. The ROI: Investing in an ACP-Ready CNC

In the Indian construction market, the margins are in the speed of installation.

- Manual Cutting: Cutting ACP with a hand-held circular saw and a guide rail is slow, dangerous, and inaccurate.

- CNC Automation: A Kataria CNC can cut an entire 10-foot facade panel with all holes, grooves, and notches in under 5 minutes.

Cost Benefit: A typical exterior cladding project that takes 10 days with manual labor can be completed in 3 days using a CNC router, drastically reducing your on-site labor costs.

Conclusion: Elevate Your Fabrication Game

ACP is the material of the future, but to unlock its potential, you need a machine that speaks its language. Kataria Tech Zone CNC Routers are designed to handle the rigors of ACP fabrication—providing the speed for signage and the precision for high-end architecture.