| Specification | Value |

|---|---|

| FEED TRAY | Single Tray |

| SIZE OF FEED TRAY | 100” * 51” Clear measurements (easy working) |

| MAXIMUM CAPACITY | Easy adjustable, process up to 50 mm. of working piece thick piece and very suitable for post forming of PVC sheet |

| POWER CONSUMPTION | 16.5 KW standard (12.5 kw Optional is also possible) |

| DOOR PROCESSING TIME | 90 Seconds |

| HEATING SYSTEM | Medium Wave Infra Red Heating Rod (India’s Fastest Heating system) |

| WORKING MODE | Mode, Manual, Auto. Auto mode is guided by Taiwan controller. No over heating is possible, no material loss |

| APPLICATION | Plywood, Block Board, MDF, HDF, AND POST FORMING ALSO |

| LAMINATION MATERIAL | PVC Foil, Mica, Veneer, Transfer film, and Paper |

| POSTFORMING MATERIAL | PVC Foam Sheet up to 6mm, Acrylic sheet up to 2.5 mm |

| VACUUM PUMP | 65m3 pump 3 HP ABB motor Specially designed to serve woodworking Industry |

| NOs OF SILICON SHEETS | 2 SHEETS |

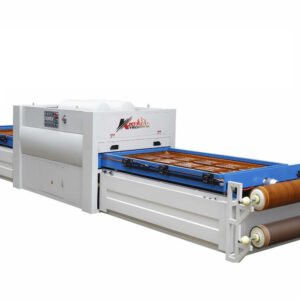

Elevate Your Craft with Precision: The Kataria Tech Zone Single Trolley Vacuum Membrane Press Machine

In the competitive landscape of woodworking, furniture manufacturing, and interior design, precision, efficiency, and flawless finishes are not just advantages – they are necessities. Introducing the Single Trolley Vacuum Membrane Press Machine by Kataria Tech Zone, a revolutionary solution engineered to redefine your production capabilities and elevate the quality of your finished products. Designed for durability, ease of use, and unparalleled performance, this machine is an indispensable asset for businesses aiming for excellence in laminating, veneering, and shaping diverse materials.

Unveiling Unmatched Performance and Versatility

The Kataria Tech Zone Single Trolley Vacuum Membrane Press Machine is a testament to cutting-edge engineering, seamlessly integrating advanced technology with robust construction. This powerhouse is specifically designed to handle a wide array of materials, from PVC and veneer to high-gloss films and various laminates, onto a multitude of substrates including MDF, particleboard, plywood, and solid wood. Its single trolley system is optimized for efficient workflow, allowing for quick loading and unloading, thereby maximizing your daily output without compromising on the quality of the press.

Key Features that Set Us Apart:

- Robust & Durable Construction: Built with heavy-duty steel and precision-engineered components, the machine is designed for continuous operation in demanding industrial environments. Its robust frame ensures stability and vibration-free performance, contributing to consistently high-quality finishes and a long operational lifespan.

- High-Efficiency Vacuum System: At the heart of our machine lies a powerful, industrial-grade vacuum pump. This system generates a consistently high vacuum pressure, ensuring uniform material adhesion and bubble-free, wrinkle-free finishes. The rapid vacuum draw time significantly reduces cycle times, boosting overall productivity.

- Precision Heating Technology: Equipped with advanced heating elements and precise temperature control, the machine ensures optimal heat distribution across the entire pressing surface. This uniform heating is critical for achieving perfect bonding and activation of adhesives, particularly important for intricate designs and varied material thicknesses.

- Single Trolley System for Optimized Workflow: The integrated single trolley design is a hallmark of efficiency. This system allows for convenient loading and unloading of workpieces, minimizing downtime between cycles. Operators can prepare the next batch while the current one is being processed, ensuring a continuous flow of production.

- User-Friendly PLC Control Interface: Operating the Kataria Tech Zone Vacuum Press is intuitive and straightforward, thanks to its advanced PLC (Programmable Logic Controller) system. The touch-screen interface provides real-time monitoring of critical parameters such as temperature, vacuum pressure, and cycle time. It allows for easy adjustment of settings, storage of multiple programs, and diagnostics, making it accessible even for operators with varying levels of experience.

- Safety Interlocks and Emergency Stops: Operator safety is paramount. The machine incorporates multiple safety features, including emergency stop buttons strategically placed, safety interlocks on access points, and overheating protection, ensuring a secure working environment.

- Versatile Material Handling: This machine is a true workhorse, capable of processing a diverse range of materials. From traditional wood veneers to modern PVC films, high-gloss laminates, and even intricate 3D designs, its versatility makes it an invaluable asset for a wide spectrum of applications.

Applications: Where Precision Meets Possibility

The Kataria Tech Zone Single Trolley Vacuum Membrane Press Machine opens up a world of possibilities for manufacturers and craftsmen across various industries:

- Furniture Manufacturing: Create stunning kitchen cabinet doors, wardrobe panels, drawer fronts, and decorative furniture components with flawless laminated or veneered finishes. Achieve seamless wraps around contoured edges and intricate profiles, adding significant value to your furniture lines.

- Interior Decoration: Produce high-quality wall panels, decorative ceiling elements, door skins, and architectural mouldings with intricate designs and superior surface finishes. The ability to bond various decorative films makes it ideal for custom interior projects.

- Shopfitting & Retail Displays: Fabricate durable and aesthetically pleasing display units, counter tops, and shelving for retail environments. The machine ensures that your fixtures not only look professional but also withstand the rigors of daily use.

- Automotive Interior Components: Ideal for laminating dashboards, door panels, and other interior trim components, providing a premium finish and enhancing durability.

- Soundproofing & Acoustic Panels: Apply various materials to create effective sound-absorbing or diffusing panels for studios, auditoriums, and commercial spaces.

- Craft & Art Projects: For specialized applications requiring precise bonding and forming of materials for artistic installations or bespoke craft items.

The Kataria Tech Zone Advantage: Beyond the Machine

Choosing the Kataria Tech Zone Single Trolley Vacuum Membrane Press Machine means investing in more than just a piece of equipment; it’s an investment in a partnership dedicated to your success.

- Expert Consultation: Our team of experienced professionals is available to provide pre-sales consultation, helping you understand the machine’s capabilities and how it can best integrate into your existing workflow. We assist you in selecting the optimal configuration for your specific needs.

- Comprehensive Training: We offer thorough training programs for your operators, ensuring they are proficient in operating, maintaining, and troubleshooting the machine effectively. This empowers your team and maximizes your return on investment.

- Dedicated After-Sales Support: Kataria Tech Zone is committed to providing exceptional after-sales service. Our dedicated support team is readily available to address any queries, provide technical assistance, and supply genuine spare parts, minimizing downtime and ensuring continuous operation of your machine.

- Quality and Reliability: Every machine undergoes stringent quality control checks before leaving our facility, ensuring it meets the highest standards of performance and reliability. We stand behind the quality of our products, offering you peace of mind.

- Innovation and Future-Proofing: We continuously invest in research and development to bring you the latest advancements in vacuum pressing technology. Our machines are designed with future expandability in mind, allowing for potential upgrades and adaptations as your business evolves.

Invest in Excellence, Invest in Kataria Tech Zone

The Single Trolley Vacuum Membrane Press Machine by Kataria Tech Zone is more than just a piece of machinery; it’s a strategic investment in your manufacturing future. It’s an investment in superior product quality, enhanced operational efficiency, reduced waste, and ultimately, increased profitability. With its robust construction, advanced technology, and comprehensive support, this machine empowers you to take on complex projects with confidence and deliver exceptional results every time.

Don’t settle for anything less than perfection. Contact Kataria Tech Zone today to learn more about how our Single Trolley Vacuum Membrane Press Machine can transform your production capabilities and help you achieve unparalleled success in your industry. Elevate your craft with precision – choose Kataria Tech Zone.

Vanita –

The lamination quality on this machine is top-tier. We use it for complex 3D designs and PVC membrane doors, and the finish is always flawless—no wrinkles or delamination. I’m particularly impressed with the Taiwan-controlled auto mode, which prevents overheating and ensures we don’t waste expensive material. The vacuum pressure is consistent and powerful. If you are looking for precision and a premium finish for your shutters or panels, this is the machine to get.

Penny –

We recently integrated the Kataria Tech Zone Single Trolley Vacuum Membrane Machine into our production line and the efficiency gains have been massive. The 90-second door processing time is a game-changer for our workflow. The Medium Wave Infra Red Heating system is incredibly fast and provides uniform heat distribution, which has completely eliminated the bubbling issues we had with our old equipment. It’s a robust, heavy-duty machine that feels built to last. Highly recommended for any professional woodworking setup!