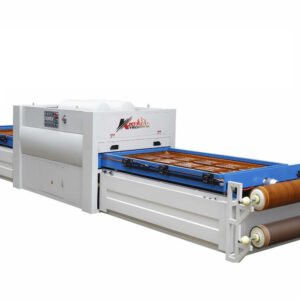

Vacuum Membrane Machines by Kataria Tech Zone: Shaping the Future of Lamination and Forming

In the modern manufacturing landscape, the demand for complex shapes, seamless finishes, and superior bonding on a variety of materials has never been higher. Kataria Tech Zone’s Vacuum Membrane Machines stand as the definitive solution for achieving these intricate requirements with unparalleled precision and efficiency. Whether it’s veneering a curved furniture panel, laminating PVC film onto kitchen cabinet doors, or thermoforming advanced composite components, our machines utilize the power of vacuum and controlled heat to deliver flawless results every time. For industries ranging from woodworking and furniture to automotive and interior decoration, Kataria Tech Zone offers cutting-edge vacuum membrane technology that transforms design possibilities into tangible, high-quality products.

The Innovation Behind Vacuum Membrane Technology

A vacuum membrane machine, often referred to as a vacuum press or 3D laminating machine, operates by drawing air from beneath a flexible membrane, creating a vacuum that applies uniform pressure across the surface of a workpiece. When combined with heat, this process allows for the precise bonding of veneers, PVC films, PET films, acrylics, and other decorative laminates onto flat, contoured, or intricately shaped substrates. The core innovation lies in the ability to apply even pressure to complex three-dimensional surfaces, eliminating bubbles, wrinkles, and inconsistencies common with traditional lamination methods. This capability is vital for modern furniture designs, bespoke interior elements, and specialized industrial components. Kataria Tech Zone’s vacuum membrane machines are engineered to harness this technology to its fullest potential, ensuring superior adhesion and impeccable finishes.

Why Choose a Vacuum Membrane Machine from Kataria Tech Zone?

Investing in a vacuum membrane machine is a strategic move for businesses aiming to expand their design capabilities, improve product quality, and enhance production efficiency. Kataria Tech Zone is committed to providing robust, reliable, and high-performance solutions backed by exceptional customer support. Here’s why discerning manufacturers across India choose our vacuum membrane machines:

Flawless Lamination on Complex Shapes: Our machines excel at laminating veneers or films onto flat, curved, and intricate 3D surfaces with uniform pressure, eliminating bubbles, wrinkles, and delamination for a pristine finish.

Superior Bonding Strength: By ensuring optimal contact and uniform pressure, our vacuum presses facilitate excellent adhesive curing and bonding, resulting in durable, long-lasting products.

Exceptional Material Versatility: Capable of processing a wide array of materials, including wood, MDF, particle board, plywood, various plastics, and composites, with a diverse range of veneers, PVC, PET, and acrylic films.

Robust & Durable Construction: Built for continuous industrial use, Kataria Tech Zone vacuum membrane machines feature heavy-duty steel frames, reliable vacuum pumps, and robust heating systems (where applicable), ensuring extended operational life and consistent performance.

High Efficiency & Productivity: Designed for quick cycle times, easy material loading, and intuitive operation, our machines significantly boost production throughput and streamline your manufacturing process.

Reliable Local Support: As a leading Indian provider, Kataria Tech Zone offers unparalleled local technical support, expert installation, comprehensive training, and readily available spare parts, ensuring maximum uptime and peace of mind for our clients.

Types of Vacuum Membrane Machines by Kataria Tech Zone: Tailored Solutions

Kataria Tech Zone offers a specialized range of vacuum membrane machines to cater to diverse production needs and material applications:

Hot Vacuum Membrane Presses (with Heating System):

These are the most common and versatile, incorporating a heating system (e.g., infrared lamps, electric heating tubes) within the vacuum chamber or platen. Heat softens the thermoforming films (like PVC, PET, acrylic) or activates adhesives for veneers, allowing them to stretch and conform perfectly to complex 3D contours under vacuum pressure.

Applications: Ideal for laminating cabinet doors, wardrobe shutters, furniture panels with decorative films, and forming intricate 3D shapes.

Configurations: Available in single-tray models (manual loading/unloading) or automated shuttle-tray systems for continuous, high-volume production.

Cold Vacuum Membrane Presses (without Heating):

These machines rely solely on vacuum pressure, without an integrated heating system. They are primarily used for laminating natural wood veneers or other flexible materials with ambient-curing adhesives onto flat or gently curved substrates.

Applications: Perfect for traditional veneering, bonding flat panels, or laminating materials that are sensitive to heat.

Key Features of Kataria Tech Zone’s Vacuum Membrane Machines

Our vacuum membrane machines are meticulously engineered with advanced features that prioritize precision, efficiency, and operator convenience:

High-Efficiency Vacuum Pump System: Equipped with powerful, reliable vacuum pumps (e.g., oil-lubricated rotary vane pumps) that quickly draw down and maintain a consistent vacuum level, ensuring optimal pressure application and superior bonding.

Advanced Heating System (for Hot Presses): Features highly efficient infrared quartz lamps or electric heating elements, strategically positioned to ensure uniform temperature distribution across the entire heating area, crucial for consistent thermoforming results.

High-Elasticity Silicone Membrane: Utilizes premium-grade, highly elastic, and tear-resistant silicone membranes capable of withstanding high temperatures (for hot presses) and stretching to conform to the most intricate 3D contours without tearing or deforming.

Robust & Stable Machine Frame: Heavy-duty, welded steel construction provides exceptional rigidity and stability, preventing deflection under vacuum pressure and ensuring long-term reliability.

Intuitive PLC-Based Control System: User-friendly touch screen interfaces allow for precise control and monitoring of vacuum levels, heating temperature, pressing duration, and automated cycle initiation. Includes error diagnostics and program storage.

Efficient Sealing Mechanism: High-quality sealing gaskets and clamping systems ensure a perfect, airtight seal around the membrane, maintaining optimal vacuum during the entire pressing cycle.

Shuttle Tray Systems (for Automated Models): Allows one tray to be loaded and unloaded while another is in the pressing cycle, significantly reducing idle time and boosting productivity in high-volume operations.

Safety Features: Equipped with emergency stop buttons, automatic pressure release valves, and safety interlocks to ensure operator protection and safe machine operation.

Integrated Work Tables & Supports: Robust work tables within the vacuum chamber (or on shuttle trays) provide a stable platform for placing workpieces and forms.

Applications Across Diverse Industries

The unparalleled versatility of Kataria Tech Zone’s Vacuum Membrane Machines makes them indispensable across a wide array of manufacturing sectors:

Furniture Manufacturing: Laminating decorative films (PVC, PET, acrylic) onto MDF cabinet doors, wardrobe shutters, drawer fronts, and creating curved or intricately profiled furniture components.

Modular Kitchen Production: Essential for producing high-quality, seamless cabinet and shutter doors with various finishes and designs.

Interior Decor & Architectural Millwork: Creating unique curved wall panels, decorative ceilings, architectural columns, and bespoke interior elements with veneered or film-laminated finishes.

Automotive Interiors: Forming dashboard components, door panels, and other interior trim parts from various plastic films onto substrates.

Display & Shopfitting: Manufacturing 3D formed display stands, point-of-sale units, and complex signage with smooth, uniform finishes.

Composite Material Production: Laying up and consolidating layers of composite materials (e.g., fiberglass, carbon fiber with resins) under vacuum to eliminate voids and achieve high strength-to-weight ratios for specialized components.

Door Manufacturing: Applying decorative skins or veneers onto door panels, including contoured designs.

Custom Woodworking: For bespoke veneering projects on complex shapes where traditional methods are not feasible.

Benefits of Investing in a Kataria Tech Zone Vacuum Membrane Machine

Integrating a Kataria Tech Zone Vacuum Membrane Machine into your operations delivers transformative advantages:

Flawless Finish & Aesthetics: Produce products with perfectly smooth, bubble-free, and wrinkle-free surfaces, enhancing their visual appeal and perceived value.

Unleash Design Freedom: Ability to seamlessly laminate onto flat, curved, and complex 3D contours, enabling the creation of intricate and modern designs.

Superior Bonding Quality: Ensure strong, durable adhesion that prevents delamination, increasing product longevity and reducing callbacks.

Increased Production Efficiency: Automate the laminating process, reduce manual labor, and shorten cycle times, leading to significantly higher output.

Reduced Material Waste: Precise pressure application and reduced defects mean less material spoilage, especially with expensive films or veneers.

Versatility of Materials: Process a wide range of substrates and laminating materials on a single machine, offering immense production flexibility.

Long-Term Reliability & ROI: Our robust machines are built for continuous, high-volume operation, ensuring maximum uptime and a healthy return on your investment for many years.

Kataria Tech Zone is dedicated to being your trusted partner in advanced lamination and forming. Our team of experts is ready to understand your specific production challenges and guide you in selecting the ideal vacuum membrane machine solution that aligns with your materials, design complexity, production volume, and budget. Empower your manufacturing process with the precision, versatility, and quality that only Kataria Tech Zone’s Vacuum Membrane Machines can provide. Contact us today to discuss your requirements and discover the perfect laminating and forming solution for your business.