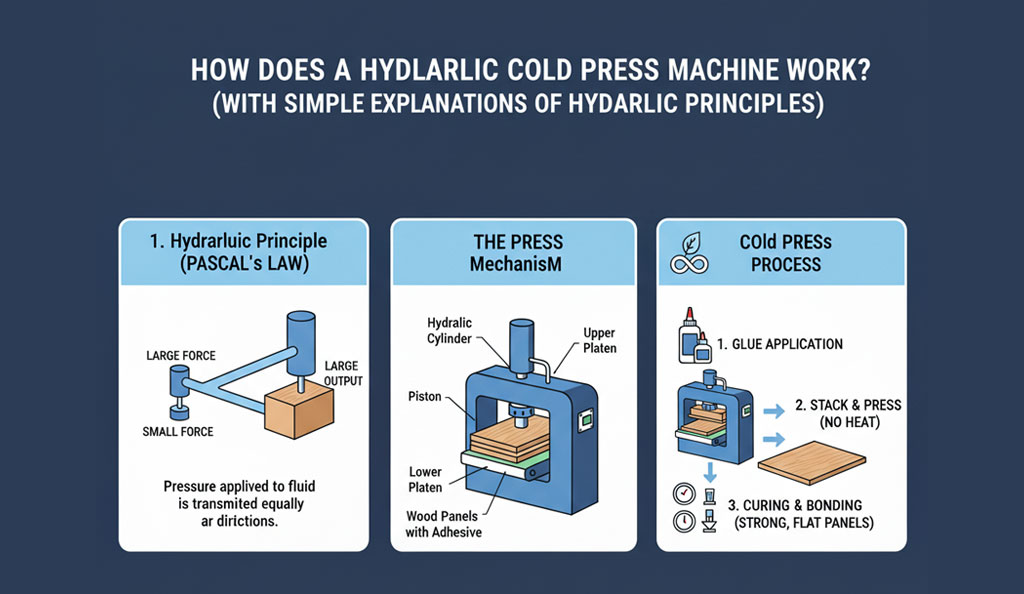

A hydraulic cold press machine operates by leveraging the scientific principles of hydraulics—specifically Pascal’s Law—to apply uniform, high pressure over woodworking materials without the use of heat. Kataria Tech Zone Punjab provides modern presses designed for woodworkers who require reliable bonding, flawless finish, and maximum efficiency.

Simple Explanation of Hydraulic Principles

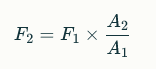

Hydraulic presses use fluid power to multiply force. According to Pascal’s Law, pressure applied at one point to a confined fluid is transmitted undiminished to all parts of the system. This principle is utilized by having a small piston (input) push hydraulic oil, generating pressure that is transmitted to a larger piston (output), resulting in a much greater force. Mathematically, this force amplification is described as:

where F2F2 is the output force, F1F1 is the input force, and A2A2 & A1A1 are the areas of the output and input pistons, respectively.

How a Hydraulic Cold Press Machine Works

- Preparation: Wood panels, veneers, or laminates are carefully loaded onto the lower platen of the press.

- Pressure Application: When the machine is activated, hydraulic cylinders (powered by a pump and motor) drive the upper platen downwards, applying uniform pressure across the surface of the materials. Multiple cylinders ensure pressure is even, eliminating weak spots.

- Bonding: The desired pressing pressure is accurately set using a gauge. Pressure is maintained for a specific time, allowing glue or adhesive to cure naturally at room temperature—no heat required.

- Release and Unloading: After curing, the pressure is released, and the finished, strongly bonded panels can be removed for further processing.

- Safety and Adjustment: Advanced models from Kataria Tech Zone incorporate safety systems, such as emergency stops, relief valves, programmable timers, and adjustable daylight opening to cater to different panel thicknesses and operator safety.

Key System Components

- Robust Frame: Built from heavy-duty steel for consistent flatness and durability.

- Hydraulic System: Includes pump, motor, multiple cylinders, oil reservoir, control valves, and manifold for precise pressure generation and control.

- Platens: Thick steel pressing plates for even pressure distribution.

- Digital Controls & Gauges: Allow for accurate pressure setting and cycle timing for different materials and adhesives.

Hydraulic cold press machines offer a clean, energy-efficient, and highly reliable solution for bonding and laminating in woodworking, making them a core asset for manufacturers and craftsmen.