Vertical and horizontal panel saws differ significantly in both their operation and space usage:

Operation

- Vertical Panel Saws: The material stands upright against a frame, and the saw blade moves either vertically or horizontally to make cuts. These saws can typically be operated by a single person. The user maneuvers the saw head for vertical (crosscutting) or locks it for horizontal (strip cutting), and the cuts are made as the saw moves downward or sideways relative to the upright panel. Because of the gravity-assisted downward motion, operation is often smoother and easier for manual models.

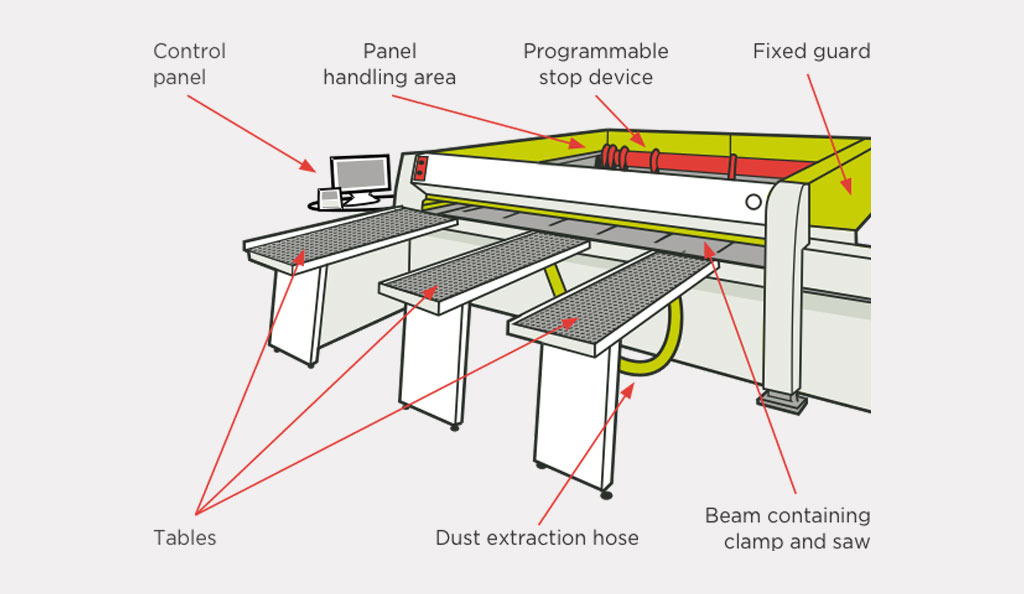

- Horizontal Panel Saws: These work like a giant table saw, where the material is laid flat on a table. The blade moves through the stationary sheet, or the table itself slides the panel into a stationary blade. Horizontal saws are designed for heavy-duty and higher-volume industrial use, allowing for stack-cutting (multiple sheets at once) and typically require one or two operators for large panels.

Space Usage

- Vertical Panel Saws: They are compact and stand against a wall, significantly reducing floor space requirements. A vertical panel saw can fit into most workshops or even smaller garages, making them ideal for shops with limited space or for mobile use. For example, one comparison found a vertical panel saw with similar performance might require about 27m² of workshop space.

- Horizontal Panel Saws: These machines occupy substantially more floor space since both the saw and the handling area for moving large panels must be on the same level. They are best suited for larger workshops or dedicated manufacturing environments, with one source noting they may require around 50m² for installation and operation.

Summary Table

| Feature | Vertical Panel Saw | Horizontal Panel Saw |

|---|---|---|

| Panel Handling | Upright, against a wall | Flat, laid on a table |

| Operator Needed | 1 (even for large panels) | 1–2 (especially for large panels) |

| Floor Space Requirement | Compact (e.g., 27m²) | Large (e.g., 50m²) |

| Typical Setting | Small/medium workshops, mobile | Large workshops, industrial |

| Productivity (Speed) | Fast for manual operation | Fastest, especially for mass cutting |

| Stack Cutting | Limited | Allows for stack cutting |

In summary, vertical panel saws maximize floor space efficiency and are easier to use for smaller operations or where space is limited, while horizontal panel saws provide higher capacity, better automation, and stack-cutting for large-scale production, at the cost of much more space usage.