Welcome to the Kataria Tech Zone blog! In the race for precision, speed, and profitability, modern woodworking businesses are increasingly relying on CNC (Computer Numerical Control) technology. But a CNC router is more than just a big cutting machine; it’s a sophisticated system built on key features that drive efficiency.

If you’re looking to invest in new equipment or upgrade your existing setup, understanding these essential features is critical to choosing a machine that will deliver a true competitive edge.

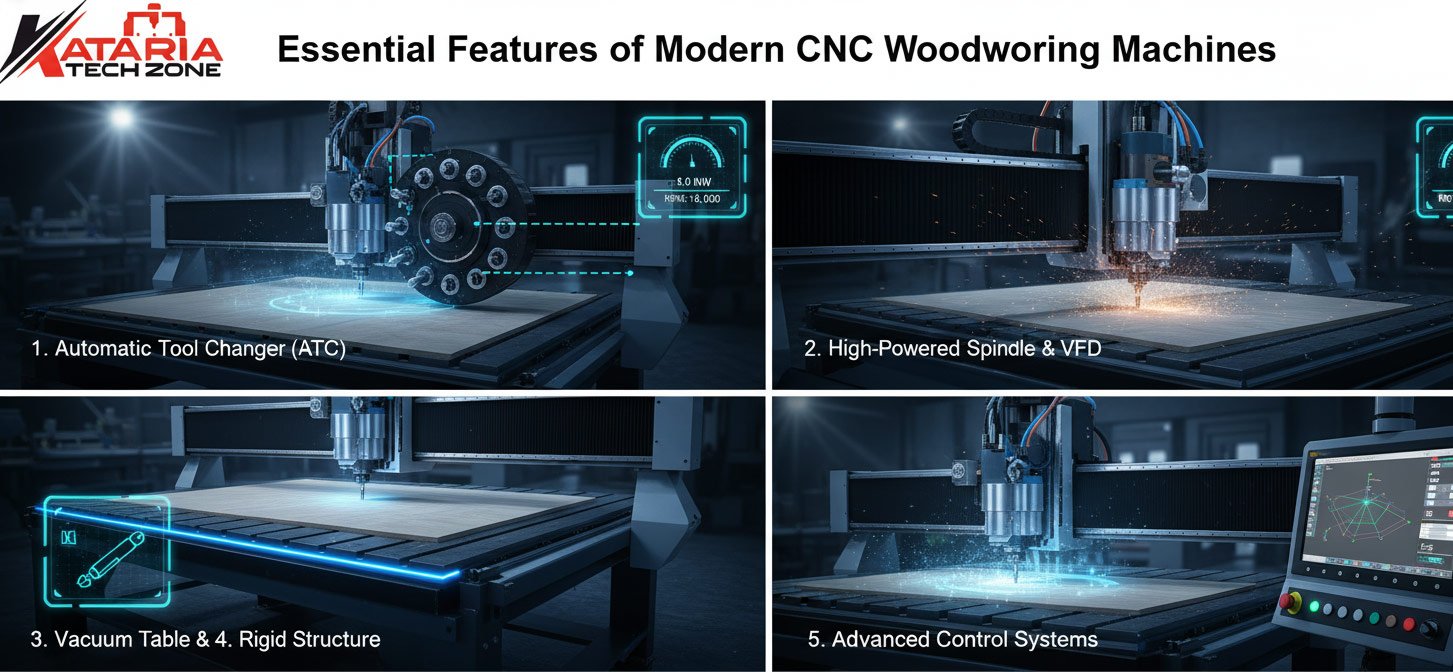

1. Automatic Tool Changer (ATC)

The ATC is perhaps the biggest productivity booster in modern CNC woodworking. It replaces the time-consuming manual process of swapping tools (bits) between different cutting operations.

- How it Works: The spindle automatically picks up and drops off tools from a magazine or rack mounted near the work area.

- The Benefit: It allows a single job requiring multiple tools (e.g., a pocketing bit, a profile bit, and a drill bit) to run unattended from start to finish. This saves immense amounts of labor time and eliminates human error in tool setting.

- Recommendation: A must-have for high-volume production and complex projects like cabinet nesting.

2. High-Powered Spindle and VFD

The spindle is the heart of the CNC machine, and its power directly impacts cutting speed, material compatibility, and overall finish quality.

- Spindle Power: Measured in kilowatts (kW) or horsepower (HP). For professional woodworking, look for a spindle power of 3.0 kW to 6.0 kW (or higher). This power is essential for deep, continuous cuts in hardwoods and sheet goods.

- Spindle Type: Industrial-grade liquid-cooled spindles are preferred over air-cooled or standard trim routers because they maintain lower operating temperatures, which is critical for long, all-day production runs.

- Variable Frequency Drive (VFD): The VFD controls the spindle’s RPM (rotations per minute). A good VFD allows for a wide speed range, letting you optimize cutting parameters for different materials and tools (e.g., lower RPMs for metals, high RPMs for wood).

3. Workholding System: The Vacuum Table

A machine is only as good as its ability to hold the material steady. For woodworking, the vacuum table is the industry standard.

- How it Works: A powerful vacuum pump creates suction across the entire bed (or zones), holding down full sheets of material (like 4′ x 8′ plywood) without the need for mechanical clamps.

- The Benefit: It ensures the material remains perfectly flat and stationary during high-speed cutting, preventing movement (chatter) that ruins a job. It also allows for edge-to-edge cutting and faster material loading/unloading.

- Recommendation: A robust vacuum pump and the ability to zone off unused parts of the table are key efficiency features.

4. Machine Structure: Rigidity and Drive System

High-speed cutting generates powerful forces. The machine’s physical construction must be rigid enough to handle these forces without deflection or vibration.

- Frame and Gantry: Look for a heavy, all-welded steel construction. Mass equals stability. A heavier machine can cut faster and deeper while maintaining precision.

- Drive System: Industrial CNCs use Rack and Pinion or Ball Screw systems. Ball screws offer superior precision, while high-quality helical rack and pinion systems provide a great balance of speed and accuracy, especially on larger machines.

- Linear Rails: The gantry movement should be guided by precision linear rails and bearing blocks, not cheaper roller wheels, for industrial-grade longevity and accuracy.

5. Advanced Control Systems

The controller is the brain of your CNC, managing motion and execution. Modern controllers offer features that simplify operation and improve output quality.

- Digital Signal Processor (DSP) Controllers: These are standalone systems (often with a handheld remote) that allow the machine to run without being tethered to a desktop computer, offering robust, dedicated control.

- Automatic Tool Measurement (Tool Setter): A sensor pad on the table that automatically measures the length of each tool. When a tool change occurs, the machine touches the tool off to the sensor, automatically calculating the new Z-axis offset. This is essential for the efficiency of ATC machines.

- User Interface: Intuitive, reliable control software (like Syntec or a robust PC-based system) is essential for programming and error-checking.

Conclusion: Investing in Future Efficiency

An investment in a modern CNC router is an investment in automation, precision, and scalability. By prioritizing features like Automatic Tool Changers, high-power spindles, vacuum workholding, and rigid construction, you are setting up your woodworking business for maximum efficiency and superior product quality.

Kataria Tech Zone is here to guide you through selecting a machine with the right combination of these essential features to meet your unique production demands.