In the modern Indian architectural landscape, WPC (Wood Plastic Composite) has emerged as the ultimate hybrid material. Combining the aesthetic warmth of wood with the industrial durability of polymer, WPC is the go-to choice for weather-resistant facades, luxury decking, and louvers.

However, the true challenge for fabricators isn’t just cutting WPC—it’s shaping it. How do you take a rigid, 12mm WPC board and wrap it around a curved pillar? How do you create seamless, “hidden-joint” edges on a premium deck?

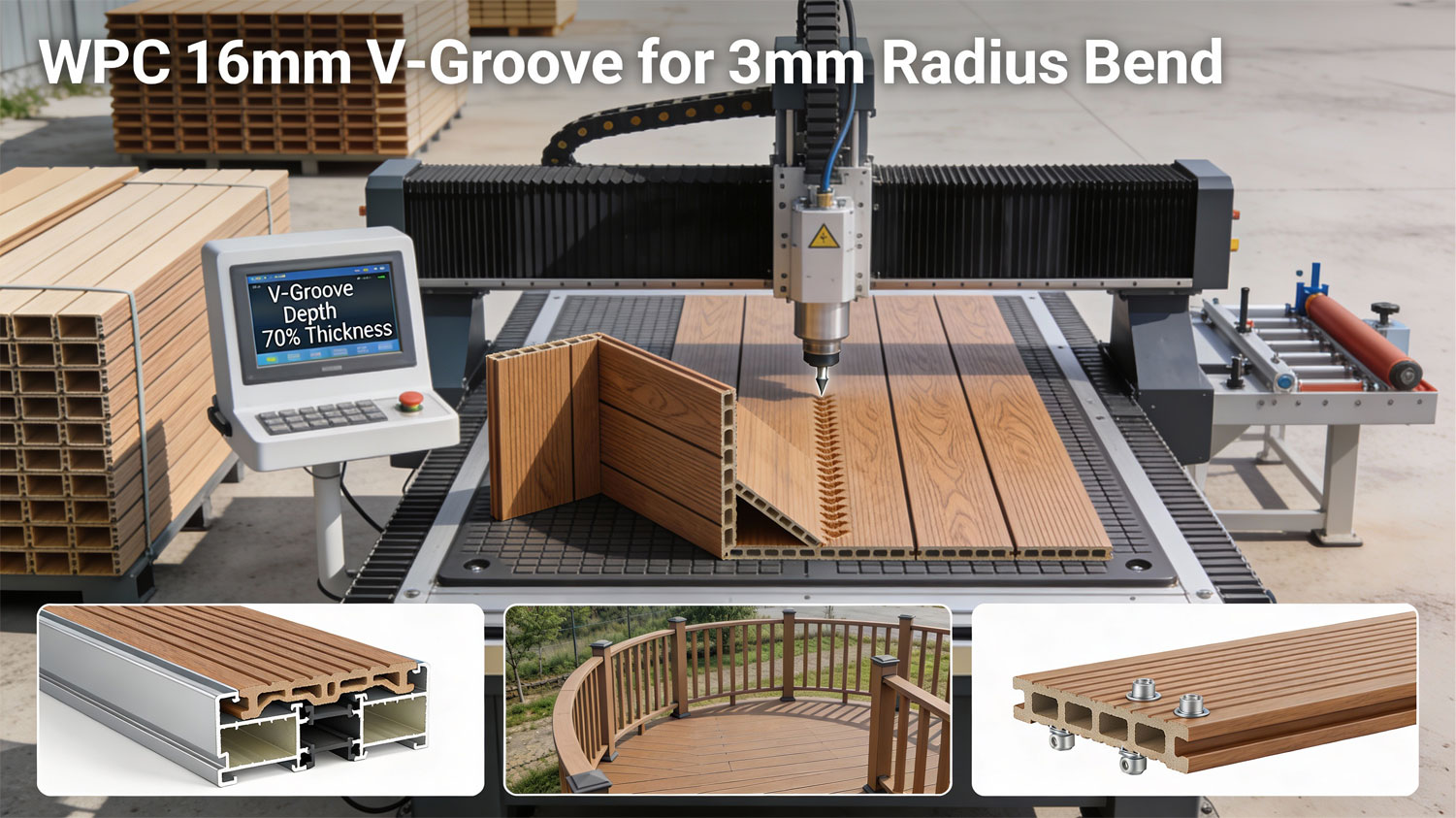

The answer lies in the precision of V-Grooving and Folding technology powered by Kataria Tech Zone CNC Routers.

1. Understanding WPC: The Material Dynamics

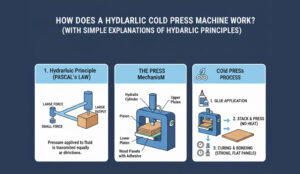

Before mastering the “Fold,” we must understand the material. WPC is a composite of wood fiber/wood flour and thermoplastics (PE, PP, or PVC).

- Thermal Memory: Unlike plywood, WPC has “thermoplastic” properties. When it gets warm, it becomes slightly more flexible.

- Density: WPC is denser than most softwoods, requiring high-torque spindles to prevent “melting” or “gumming” of the bit.

- Expansion/Contraction: WPC expands more than wood. CNC precision ensures that the “gaps” left for expansion are mathematically perfect across a 100-meter facade.

2. The Art of the V-Groove: How it Works

The “V-Groove” is a technical process where the CNC router removes a triangular section of material from the back of the panel, leaving only a thin “hinge” of the outer skin (usually 1mm to 2mm thick).

The Mathematical Secret

To create a perfect 90-degree fold, the CNC must be calibrated to a depth tolerance of ±0.1mm.

- Too Deep: The hinge snaps, and the panel is ruined.

- Too Shallow: The panel won’t fold, or the corner will be “fat” and unprofessional.

Kataria Tech Zone CNCs utilize high-resolution Z-axis sensors that ensure the depth of the V-groove remains constant, even if the WPC sheet itself has slight thickness variations.

3. Creating Curved Facades: From Rigid to Fluid

One of the hottest trends in 2025 is the curved exterior facade. Traditionally, these were made with expensive, custom-molded plastics. With a Kataria CNC, you can create them using standard flat WPC panels.

The “Kerfing” Technique

By programming the CNC to cut a series of closely spaced, parallel V-grooves (a process called kerfing), a rigid WPC board becomes as flexible as a piece of rubber.

- Tight Curves: Closer grooves (e.g., every 5mm).

- Wide Curves: Spaced grooves (e.g., every 20mm).

This allows fabricators to wrap WPC around circular columns, curved balconies, and organic architectural shapes without any visible joints on the exterior face.

4. Decking Edges: The “Waterfall” Finish

For premium decking projects, visible “end-grains” or plastic edges are a sign of poor craftsmanship. High-end clients demand the “Waterfall Edge”—where the top deck board seamlessly folds over the side to meet the ground.

Why CNC is Mandatory for Decking Edges:

- Compound Miters: For decks with non-90° angles, the CNC calculates the exact miter required for a flush fit.

- Anti-Slip Grooving: The CNC can simultaneously cut the V-groove for folding and the “anti-slip” texture on the top surface.

- Expansion Joints: Automated nesting ensures that every board has the exact 5mm gap required for Indian monsoon/summer cycles.

5. Technical Requirements: The Kataria Advantage

To handle WPC effectively, a CNC router needs more than just power; it needs Control.

A. Spindle Speed vs. Heat Management

WPC has a tendency to melt if the bit stays in one place too long. Our machines are equipped with variable-frequency drives (VFDs) that allow you to fine-tune the RPM (usually between 14,000 and 18,000) to match the feed rate, ensuring the plastic doesn’t “weld” back to the panel.

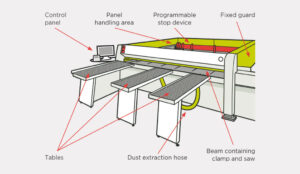

B. Dust Extraction

WPC dust is heavy and “static.” Standard vacuums often fail. Kataria Tech Zone provides high-volume dust collectors with anti-static hoses to ensure your tracks stay clear and your “V” depth remains accurate.

C. Vacuum Bed Power

WPC sheets are often heavy and slightly bowed. A standard T-slot table won’t cut it. Our multi-zone vacuum beds provide massive “hold-down” force, flattening the panel so the V-groove depth is identical from the first inch to the last.

6. The Profit Logic: Why Fabricators are Switching

The ROI (Return on Investment) for a CNC in the WPC sector is massive:

- Waste Reduction: Manual V-grooving often results in a 15% breakage rate. CNC reduces this to less than 1%.

- Labor Efficiency: One Kataria CNC can produce 40 linear meters of V-grooved facade panels in the time it takes two men to do 5 meters manually.

- Premium Pricing: You can charge a 30-40% premium for “Seamless Curved Facades” compared to standard flat-panel installation.

7. Maintenance and Tooling for WPC

WPC is surprisingly abrasive because of the wood fibers and mineral fillers.

- Bit Type: Use PCD (Polycrystalline Diamond) or Coated Carbide bits. While more expensive, they last 10x longer than standard steel bits when cutting WPC.

- Daily Cleaning: Always clear the V-groove path. Even a small chip under the sheet can change the “hinge” thickness and cause a fold to snap.

Conclusion: Shaping the Future with Kataria Tech Zone

The future of exterior design in India is curved, seamless, and durable. By combining the material science of WPC with the precision of a Kataria Tech Zone CNC Router, you aren’t just a carpenter or a contractor—you are a high-tech fabricator capable of executing designs that were once considered “impossible.”