The interior design industry in India is undergoing a massive transformation. From luxury apartments in Mumbai to boutique cafes in Delhi, the demand for 3D textured wall panels and custom decorative moldings is at an all-time high.

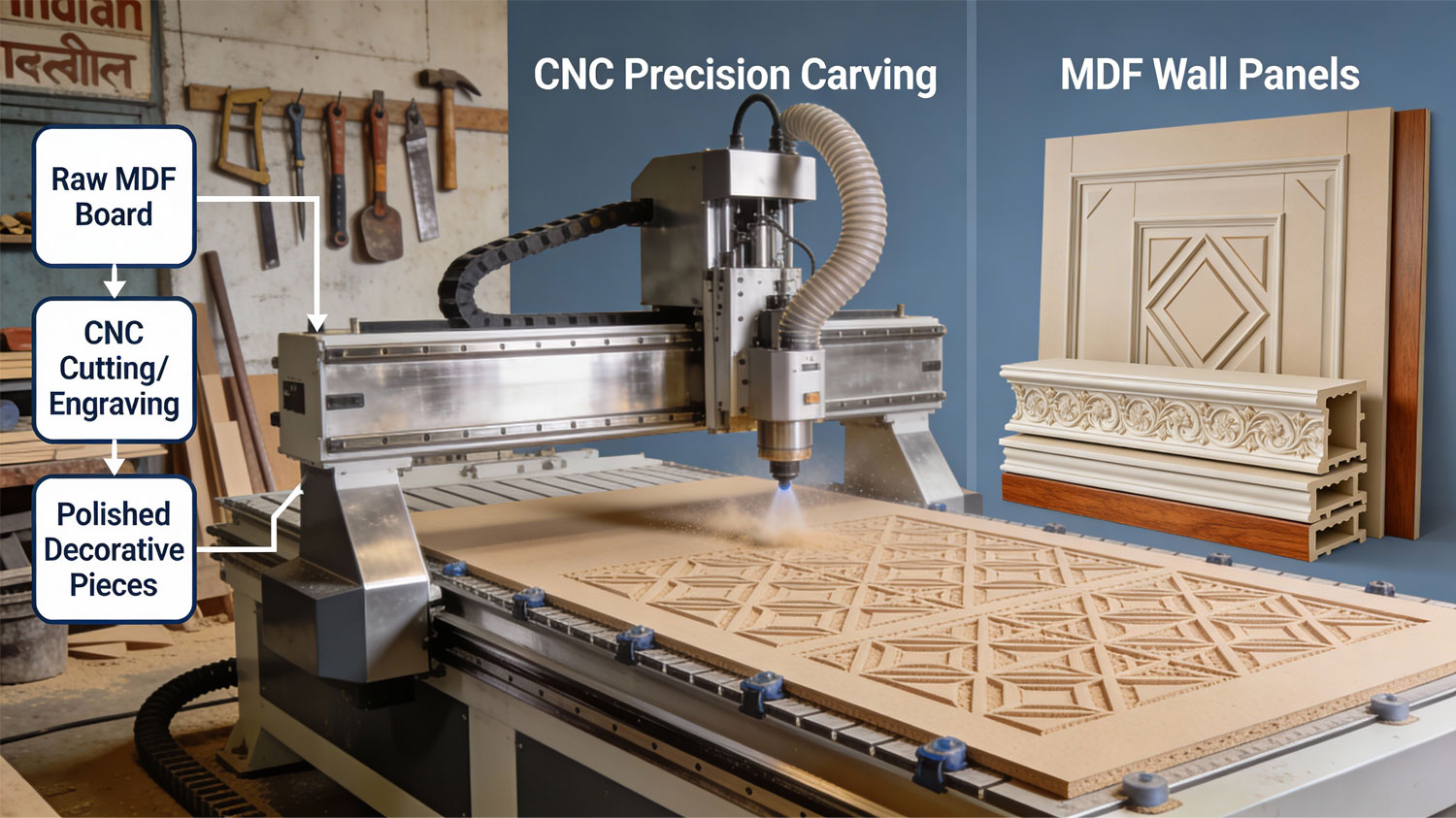

For the modern carpenter or factory owner, producing these intricate designs manually is nearly impossible. This is where Kataria Tech Zone CNC Routers come into play. In this guide, we explore how CNC technology turns a simple sheet of MDF into a high-value architectural masterpiece.

1. Why MDF? The Perfect Canvas for CNC

MDF (Medium Density Fiberboard) is the “gold standard” for CNC routing in interior decor. Unlike solid wood, MDF:

- Is Isotropic: It has no grain, meaning the CNC bit can move in any direction without tear-out.

- Is Cost-Effective: It allows for high-profit margins on decorative items.

- Takes Paint Beautifully: Once routed, it provides a smooth surface for PU (Polyurethane) or deco paints.

2. Designing the Vision: CAD to CAM

The process starts with software. Designers use CAD (Computer-Aided Design) like AutoCAD or CorelDRAW to create patterns.

Popular Patterns in 2025:

- Geometric Jali: Intricate cut-outs for partitions.

- Wave & Dune Panels: Smooth, 3D flowing textures that mimic sand or water.

- Fluted Panels: Vertical “ribbed” designs currently trending in modern living rooms.

- Classic Boiserie: Creating traditional wall moldings using a single sheet of MDF rather than individual strips.

3. The Technical Process: How Kataria CNCs Deliver Precision

Step 1: Tool Selection

To achieve professional results, tool selection is key:

- Ball-Nose Bits: Essential for 3D textures like waves.

- V-Bit (Engraving): Used for sharp, clean lines in moldings and classic designs.

- Straight Compression Bits: For clean, burr-free cutouts through the entire sheet.

Step 2: High-Speed Precision

Kataria Tech Zone machines utilize high-frequency spindles (3kW to 9kW). This speed is crucial for MDF; if the spindle is too slow, the friction causes the MDF to burn. Our CNCs maintain a constant torque to ensure every “wave” or “groove” is identical.

Step 3: Vacuum Bed Stability

MDF dust is fine and can be slippery. Our Vacuum Table technology ensures the sheet doesn’t move by a single millimeter during the process, which is vital when performing deep 3D carves that take 1-2 hours to complete.

4. Creating Decorative Moldings: The New “Standard”

Traditionally, moldings were made by running wood through a molder or shaper. With a CNC, you can create Curved Moldings—something nearly impossible with traditional machines.

- Custom Arches: Easily create moldings for arched doorways.

- Seamless Corners: The CNC can cut the miter joints and the profile simultaneously, ensuring a perfect fit every time.

5. Profitability: The Business of CNC Panels

Let’s look at the numbers in the Indian market:

- Raw MDF Sheet (8×4 ft): Approx. ₹1,800 to ₹2,500.

- CNC Processing Time: 45 minutes to 2 hours.

- Market Value of Finished 3D Panel: ₹6,000 to ₹12,000 (depending on design complexity and finish).

By investing in a Kataria Tech Zone CNC, a workshop can process 4-6 panels a day, leading to a massive increase in daily revenue compared to traditional furniture making.

6. Finishing Touches: From Raw to Luxury

A CNC-routed panel is only as good as its finish.

- Sanding: Use 220-320 grit sandpaper on the routed edges.

- Sealing: MDF edges are porous. Use an MDF sealer or a diluted wood glue mix.

- PU Coating: High-gloss or Matte PU finishes turn an MDF panel into a luxury product.

Why Choose Kataria Tech Zone for Your Decor Business?

At Kataria Tech Zone, we understand that for wall panels, smoothness is everything. Our machines are built with:

- Heavy-Duty Frames: To eliminate vibration, which causes “stepping” marks on 3D panels.

- Advanced Dust Collection: To keep your shop clean from the heavy dust generated by MDF routing.

- Lifetime Technical Support: We help you calibrate your machine for the perfect “wave” or “jali” design.

Conclusion

Creating MDF wall panels and moldings with CNC technology is no longer a luxury—it’s a necessity for any wood business that wants to stay competitive in the modern interior design market. It allows for unlimited creativity, zero manual error, and significantly higher profit margins.