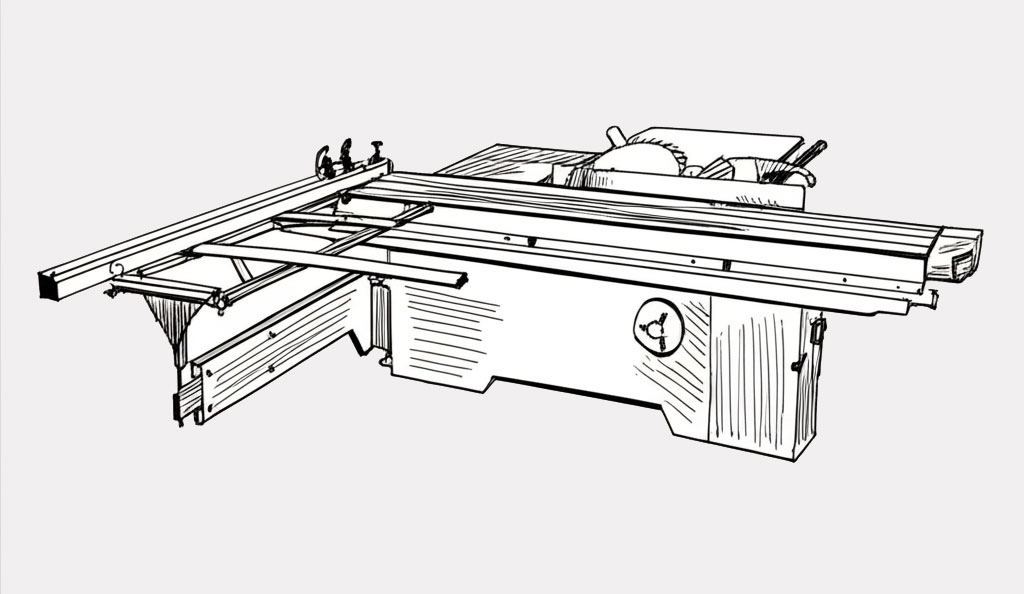

A panel saw significantly improves efficiency compared to traditional manual cutting methods in several ways:

- Precision and Accuracy: Panel saws enable highly accurate and repeatable cuts. Unlike hand-held saws or improvised manual setups, panel saws feature guides, fences, and measurement systems (often digital or laser-guided) that ensure straight, clean, and dimensionally exact cuts every time. This reduces material waste from incorrect cuts and leads to better-fitting components.

- Speed and Productivity: These machines are designed to process large panels quickly. Cutting large sheets (like plywood or MDF) can be difficult and slow with manual tools, but a panel saw allows an operator to position the sheet and make fast, controlled cuts. Automated or CNC models can execute multiple cuts in a fraction of the time, equaling the output of several operators using manual saws.

- Reduced Labor and Fatigue: Panel saws simplify handling heavy or cumbersome sheets. The material may be held upright (vertical models) or supported on a sliding table, minimizing the physical strain on operators and allowing one person to safely cut large panels. This reduces workforce requirements and operator fatigue, leading to greater throughput.

- Versatility: A panel saw can perform a variety of cuts—crosscuts, rip cuts, bevels, miters—on a variety of materials and sheet sizes, often without elaborate setup changes. This streamlines workflow and limits downtime for tool changes or repositioning.

- Safety: Panel saws incorporate numerous safety features like blade guards, emergency stops, and better material support, minimizing the risk of accidents. The stability and controlled feed mechanisms further reduce the chance of kickback or operator injury common with handheld methods.

- Material Handling Efficiency: Especially with vertical panel saws, the need for large work surfaces is minimized, and handling is simplified, leading to less damage and waste. Material support means cuts can be made with confidence, reducing scrap and maximizing usable output from each sheet.

In summary, panel saws make cutting large sheet goods faster, more precise, safer, and less labor-intensive than traditional manual sawing methods, which is why they’re considered essential equipment in modern woodworking and carpentry shops.