Functions: Gluing, Welting, Pressing, End Cutting, Rough Trimming, Fine Trimming, Edge Scraping, Polishing.

| Size | 4450*700*1550mm | Air pressure | 0.7mpa-0.8mpa |

|---|---|---|---|

| Weight | 1600 kg app. | Heating power of glue | 1.5kw |

| Bander width | 10-55mm | Preheating power | 0.3kw |

| Bander thickness | 0.4-3mm | Transmission power | 0.55kw |

| Min process length | 80mm | Conveyor motor power | 2.2kw |

| Min process width | 45mm | End cutting motor power | 0.55kw*2 |

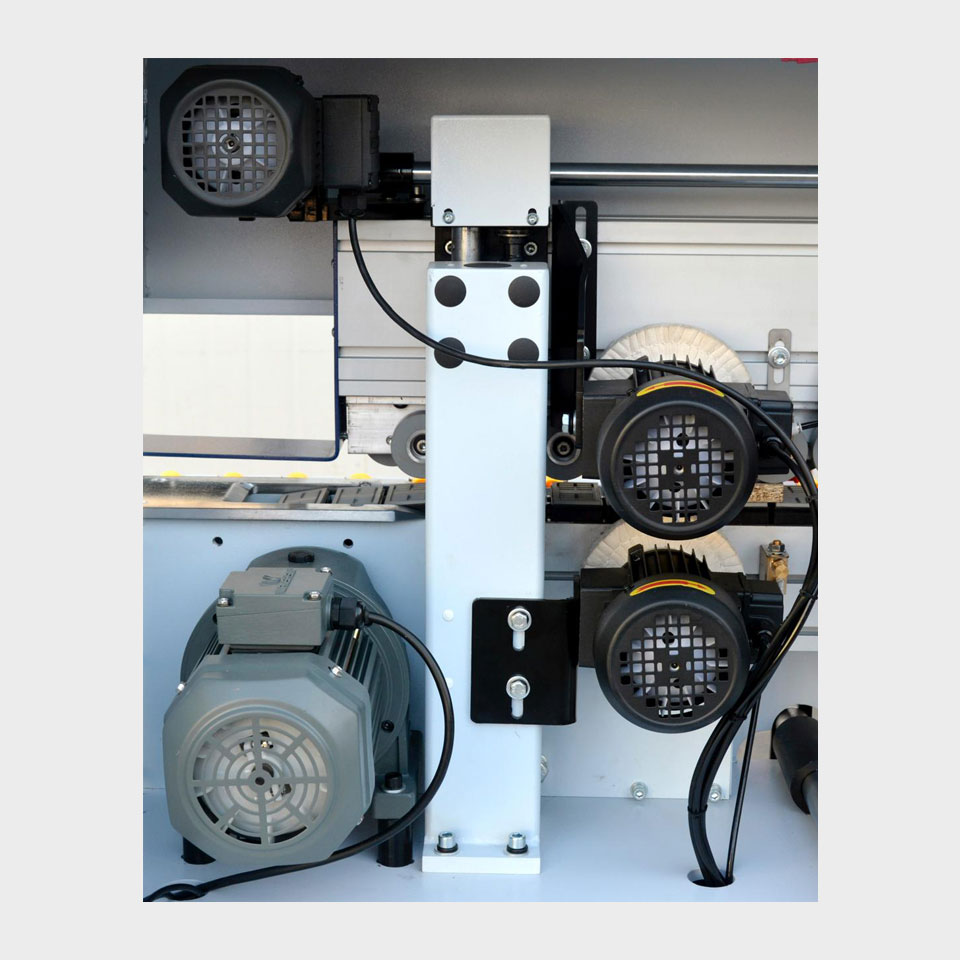

| Feed speed | 18m/20m/22m/min | Rough trimming motor | 0.75kw*2 |

| Total power | 11kw | Fine trimming motor | 0.75kw*2 |

| Pasting Roller | 6 pcs |

Salient Features:

- Touch Screen – High-definition DELTA screen, fast response, no accidental touches.

- Optimized Speed – Runs at 14m/min, ensuring high efficiency with a flawless finish.

- Pressing &. Glue System – 3-roller system ensures precise glue application for thick &. thin tapes.

- Scraping – Alloy R-knife for a smooth, refined edge finish.

- Centralized Lubrication – Auto oil injection reduces wear&. extends machine life.

- Motorized Lofting – Electric height adjustment for quick, precise setup.

Precision Perfected: Introducing the Rough & Fine Trimming Edge Banding Machine by Kataria Tech Zone, Amritsar

In the dynamic world of furniture manufacturing and woodworking, the pursuit of flawless finishes and robust durability is paramount. Every piece, from a custom-designed cabinet to a mass-produced panel, demands precision and quality at every stage. At the heart of achieving this lies superior edge banding – a process that transforms raw, exposed edges into seamless, aesthetically pleasing, and highly durable surfaces. Kataria Tech Zone, a name synonymous with innovation and reliability in woodworking machinery, proudly presents its state-of-the-art Rough & Fine Trimming Edge Banding Machine, engineered to meet the rigorous demands of modern production facilities in Punjab, Amritsar, and beyond.

This advanced machine represents a significant leap forward in edge banding technology, designed to deliver unparalleled accuracy, efficiency, and consistent quality. By integrating both rough and fine trimming capabilities into a single, cohesive unit, Kataria Tech Zone empowers manufacturers to achieve a factory-perfect finish with minimal effort and maximum output.

The Art of Edge Banding: Why Precision Trimming Matters

Edge banding is far more than just applying a strip of material; it’s a meticulous process that dictates the final look, feel, and longevity of a product. Without proper edge banding, furniture and panels are susceptible to moisture ingress, chipping, and an unfinished appearance that detracts from their value. The journey from a raw panel to a perfectly edged component involves several crucial steps, with trimming standing out as a critical phase that defines the quality of the joint.

Traditionally, achieving a perfect trim often involved multiple passes or even manual finishing, leading to inconsistencies, increased labor costs, and slower production times. Kataria Tech Zone’s Rough & Fine Trimming Edge Banding Machine addresses these challenges head-on, offering an integrated solution that streamlines the process and elevates the standard of finish.

Rough Trimming: This initial stage involves the rapid removal of excess edge banding material that overhangs the panel. The rough trimming unit is equipped with robust cutters designed for efficient material removal, ensuring that the bulk of the excess is swiftly and accurately taken off. This prepares the edge for the subsequent, more precise, fine trimming operation. The goal here is speed and effective material reduction without compromising the integrity of the bonded edge.

Fine Trimming: Following the rough trim, the fine trimming unit takes over, employing high-frequency motors and precision cutters to meticulously shave off any remaining excess, achieving a perfectly flush and smooth edge. This stage is where the magic happens, transforming a merely functional edge into a seamless, almost invisible transition between the panel and the edge band. The precision of the fine trimming unit ensures that there are no visible marks, ripples, or imperfections, delivering a finish that truly speaks of quality craftsmanship.

Unveiling the Technological Marvel: Key Features and Specifications

The Kataria Tech Zone Rough & Fine Trimming Edge Banding Machine is a testament to superior engineering and a deep understanding of woodworking demands. Its design incorporates a suite of features that contribute to its exceptional performance:

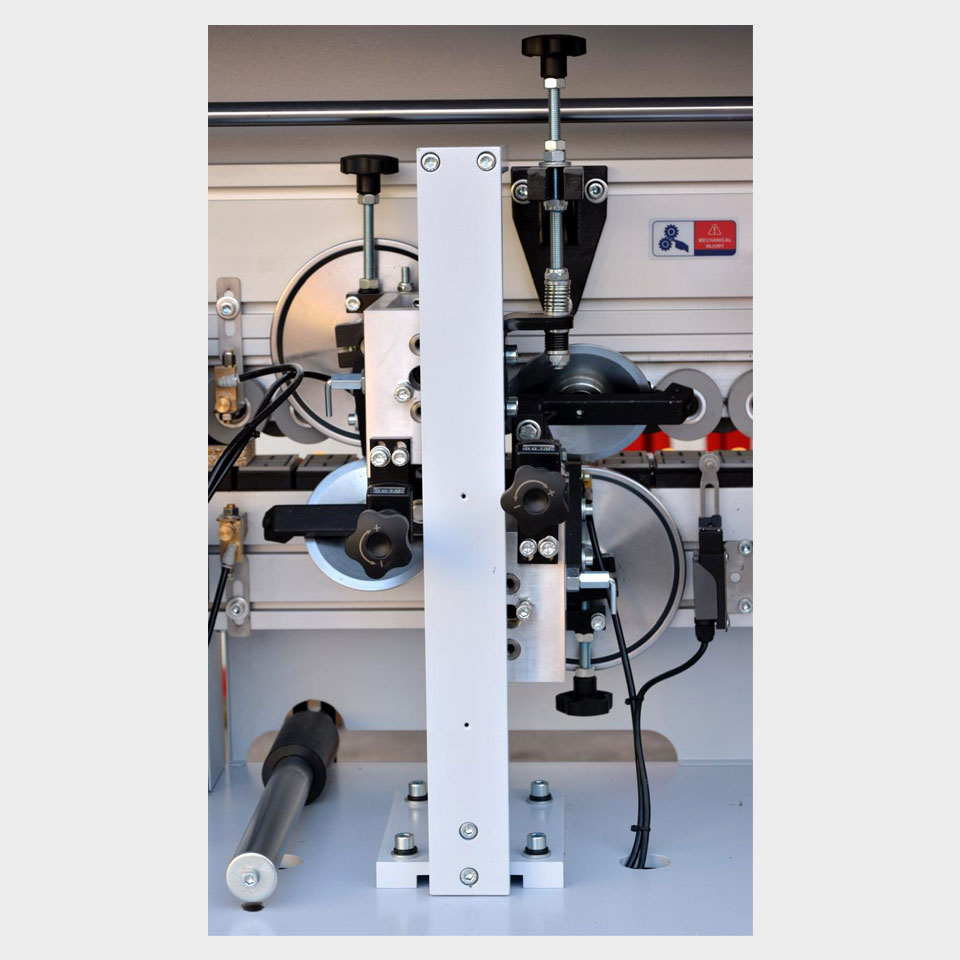

- Integrated Trimming Units: The cornerstone of this machine is its dual-stage trimming system. High-quality, durable cutters in both the rough and fine trimming units operate sequentially to provide a comprehensive and precise finish. These units are often pneumatically controlled and can be quickly adjusted for different edge band thicknesses, ensuring versatility across various projects.

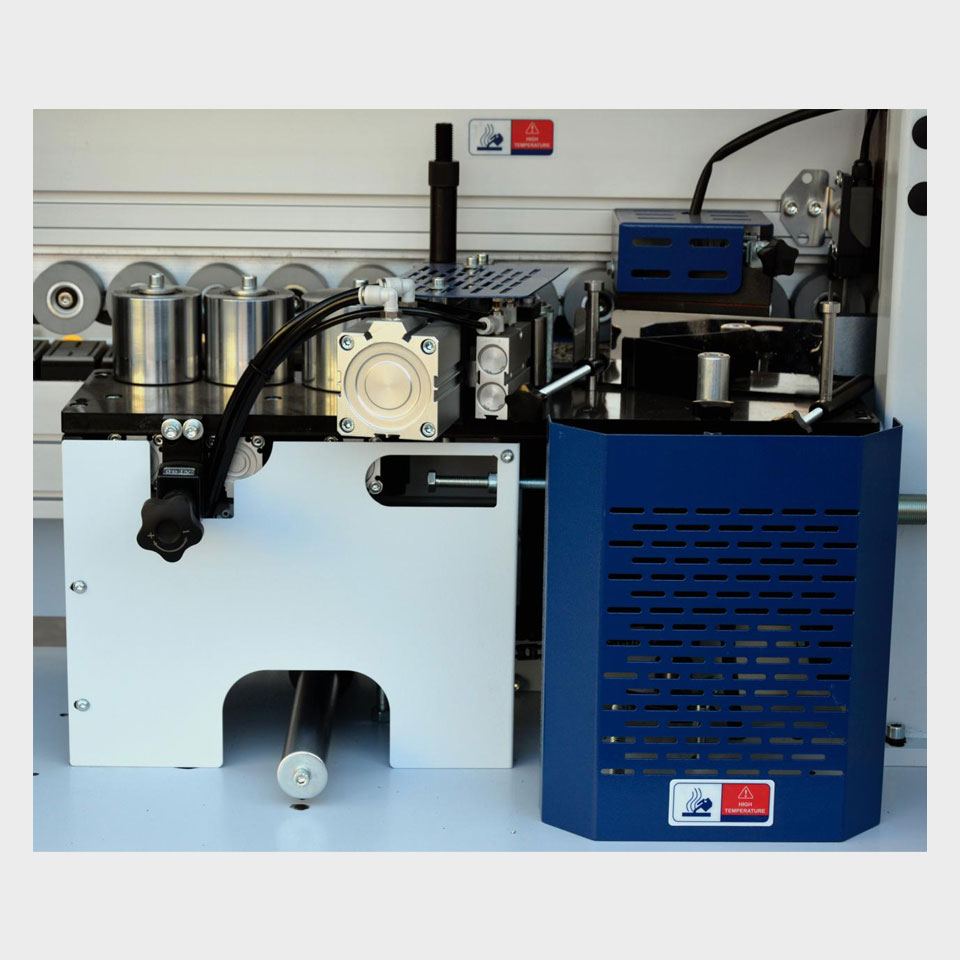

- Robust Glue Pot System: The machine features an advanced glue pot system, typically utilizing hot-melt adhesive for strong and immediate bonding. Key aspects include:

- Optimal Heating: Quick heating capabilities minimize downtime, allowing for faster production starts.

- Consistent Application: Precision glue rollers ensure a uniform and consistent layer of adhesive, crucial for strong and durable bonds.

- Variable Capacity: The glue pot is designed to hold sufficient adhesive for continuous operation, reducing the need for frequent refills.

- Precision Panel Feeding System: A heavy-duty conveyor or belt system ensures smooth and consistent panel movement through the machine.

- Adjustable Feed Speed: Variable feed speeds allow operators to optimize production based on material type and complexity of the edge.

- Secure Clamping: Pressure rollers and a robust feed chain securely hold the panel, preventing shifting and ensuring accurate trimming.

- Intuitive Control System: Modern machines feature user-friendly PLC (Programmable Logic Controller) or touchscreen interfaces. This allows for:

- Easy Operation: Simple input of parameters such as edge thickness, panel height, and feed speed.

- Real-time Monitoring: Operators can monitor the machine’s status, track production, and identify any issues promptly.

- Diagnostic Capabilities: Built-in diagnostics assist in troubleshooting and minimize downtime.

- Durable Construction: Built with a heavy-duty steel frame, the machine is designed for stability, minimal vibration, and long-term reliability even under continuous operation. High-quality components from renowned international brands are often integrated, guaranteeing performance and longevity.

- Efficient Dust Collection: Integrated dust collection ports are crucial for maintaining a clean working environment and ensuring the longevity of precision components. Effective dust extraction prevents debris from interfering with the trimming process and prolongs the life of cutters.

- Versatile Material Handling: This machine is capable of processing a wide range of edge banding materials, including PVC, ABS, melamine, veneer, and solid wood strips, on various panel types such as MDF, particle board, plywood, and solid wood boards. It accommodates diverse panel and edge thicknesses, making it suitable for a broad spectrum of applications.

- Optional Enhancements: Depending on the model and specific requirements, the machine may also include:

- Pre-milling Unit: For squaring and cleaning panel edges before glue application, ensuring a perfectly smooth surface for banding.

- End Trimming Unit: For precisely cutting the edge band at the start and end of the panel.

- Corner Rounding Unit: To create aesthetically pleasing rounded corners, eliminating sharp edges.

- Scraping Unit: For removing any residual glue or imperfections, leaving a truly seamless finish.

- Buffing Unit: To polish the edged surface, enhancing its smoothness and visual appeal.

Benefits That Drive Success

Investing in Kataria Tech Zone’s Rough & Fine Trimming Edge Banding Machine translates into a multitude of tangible benefits for woodworking businesses:

- Unmatched Precision and Finish: The dual-stage trimming ensures a consistently smooth, flush, and virtually invisible edge, elevating the aesthetic quality of your finished products and meeting the highest industry standards.

- Enhanced Productivity: Automation of the trimming process significantly reduces manual labor and speeds up production cycles, allowing you to process more panels in less time. This translates directly to higher output and improved profitability.

- Cost Efficiency: Minimizing material waste through precise trimming and reducing rework due to imperfect edges leads to substantial cost savings. Furthermore, the machine’s efficiency optimizes labor utilization.

- Superior Durability: A perfectly bonded and trimmed edge provides exceptional protection against moisture, impact, and daily wear and tear, significantly extending the lifespan of your furniture and panels.

- Versatility in Production: The ability to handle various edge band materials and panel thicknesses makes the machine highly adaptable to diverse project requirements, from custom pieces to high-volume production runs.

- Ease of Operation and Maintenance: User-friendly controls and robust construction simplify operation and reduce maintenance needs, ensuring reliable performance over years of service.

- Competitive Advantage: Delivering consistently high-quality products with impeccable edge finishes sets your business apart in a competitive market, attracting more clients and fostering customer loyalty.

Applications Across Industries

The applications of the Kataria Tech Zone Rough & Fine Trimming Edge Banding Machine are vast, catering to a wide array of industries:

- Residential Furniture: Cabinets, wardrobes, tables, chairs, beds – achieving a premium finish on all types of home furniture.

- Office Furniture: Desks, partitions, storage units – ensuring durability and a professional appearance in commercial settings.

- Modular Kitchens: Creating seamless and water-resistant edges for kitchen cabinets and countertops, crucial for longevity in humid environments.

- Interior Decor: Panels for wall cladding, decorative elements, and custom interior solutions.

- Shopfitting and Retail Displays: Producing durable and aesthetically pleasing fixtures for retail spaces.

- Educational Institutions and Hospitals: Manufacturing sturdy and hygienic furniture that can withstand heavy use.

Why Kataria Tech Zone, Amritsar?

Located in Amritsar, Punjab, Kataria Tech Zone stands as a beacon of engineering excellence in the woodworking machinery sector. Our commitment goes beyond just manufacturing machines; we build partnerships based on trust, quality, and unwavering support.

Choosing Kataria Tech Zone means:

- Local Expertise, Global Standards: We combine the agility and understanding of a local enterprise with manufacturing processes that adhere to international quality benchmarks.

- Dedicated After-Sales Support: Our relationship doesn’t end with a sale. We provide comprehensive after-sales services, including installation, operator training, readily available spare parts, and prompt technical assistance to ensure your machine operates at peak performance.

- Innovation at Core: We continuously invest in research and development to bring cutting-edge solutions that empower our customers to stay ahead in their respective industries.

- Value-Driven Solutions: We believe in offering machinery that provides exceptional value – a perfect balance of advanced features, robust construction, and competitive pricing.

- Customer-Centric Approach: Your success is our priority. We work closely with clients to understand their unique needs and provide tailored solutions that optimize their production processes.

The Rough & Fine Trimming Edge Banding Machine by Kataria Tech Zone is more than just a piece of equipment; it’s an investment in the future of your woodworking business. It’s a commitment to superior quality, enhanced efficiency, and a finish that elevates every product you create.

Discover the difference precision makes. Contact Kataria Tech Zone today for a detailed consultation, a live demonstration, or to request a personalized quote. Let us help you transform your production capabilities and achieve unparalleled excellence in edge banding.

There are no reviews yet.